The production process of jewelry is mainly based on the shape of the design drawing or the idea in mind and transforming it into something that exists. The hands-on production process does divide into two ways:

1. Directly use metal, gemstone, and other materials to shape

Jewelry works like the picture below, made of metal materials. We select the corresponding metal plate or wire and various shape tools for this type of jewelry, combined with the basic technology of metal production, annealing, bending, embossing, forging, welding, making surface texture and texture, polishing, etc. The primary product is complete.

This type of jewelry is complete in one's studio or a small space with some essential tools. It is suitable for some fashion jewelry, etc. The production process is not very difficult.

In addition, there is also a kind of production that mainly adds a unique color glaze effect on the metal surface, increasing the production process. For example, the work in the picture below is the primary production steps, and the production steps of the enamel process are added, such as metal base making, glaze drying, high-temperature firing, grinding, polishing, etc. In addition, if it is the effect of some other unique processes, it is the production steps of different methods.

Second, the production process of traditional commercial jewelry

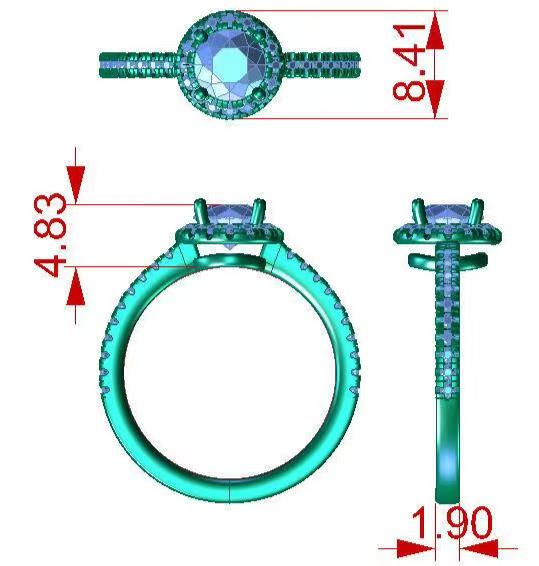

In producing conventional commercial collections, the first step is to make a pattern based on the design drawing (the two-dimensional plane design sketch turned into a three-dimensional thing). The engraving step can be hand-carved wax or 3D computer modeling.

After the printing finish, wax trees and lost wax casting are on schedule.

The purpose of planting wax trees is to replicate the production in batches, improve the efficiency of this link, and concentrate the things to be cast together. After the wax tree fix, it is put into a steel cup, poured into gypsum, and then entered into a high-temperature furnace, where the wax mold melts and disappears, forming a negative cavity. Then pour the molten metal liquid into the negative hole to get the metal tree.

That is to say, the jewelry we see on the market is such a metal tree before it becomes a finished product.

The next step is to cut the jewelry from the metal tree. Cutting it become the nozzle, and the metal surface will have a grainy, frosted, or matte texture, and subsequent steps such as filing, grinding, and polishing are required. Jewelry needs diamonds to set, and it is also necessary to establish the pre-selected diamonds or gemstones on the metal base in combination with the setting process.

For different artistic and design effects, designers and artisans have developed various inlay methods. Additional inlaid process steps are slightly different but generally the same. After all the previous actions finish, the final grinding, polishing and cleaning, quality inspection, and subsequent packaging and other processes are carried out, thus completing the entire process of making a piece of commercial jewelry.

The above are the two methods of jewelry production introduced. You can try them separately to experience different effects without craftsmanship and find a more suitable way for your presentation.

Contact: Lee

Phone: 008615812571762

E-mail: le@lerings.com

Whatsapp:008615812571762

Add: 3F,#4 ShangXing Road, XingAn ChangAn Town, DongGuan,China

We chat