The most successful business model in the apparel industry is mass luxury goods: the family that provided high-quality fashion apparel products to aristocrats in the past has maintained workshop-style production to ensure high-end handicrafts and meticulous work. After the Industrial Revolution, the fashion business gradually prospered, and the capitalists with a keen sense of smell discovered the opportunity for huge profits. They occupied these family brands through commercial wars and transformed them into large-scale production. In modern retail marketing, mass-produced industrial products are hand-made. A new business model was born to the middle class and the nouveau riche: luxury.

________________________________________

One of the characteristics of luxury goods is the large logo and brand-specific patterns, which are conspicuous enough to identify the brand. And to make money quickly, they now rarely sell clothing (clothing is generally only sold in flagship stores), and standardized products such as bags and perfumes are easier to reduce the cost of inventory redundancy. The process from reception to sales is faster.

When it comes to Hermès, it is necessary to talk about the concept of top quality: in this war, a few family brands insisted on not being acquired, operating independently, pressing on hand-made and using traditional rare raw materials, and continuing to serve the real high-end people, such as the royal family, the old The Qian family, the top elites in the business world, etc., whose trademarks are small or even invisible, can be classified as leading products. Due to the niche market, most of these brands are not well developed, but Hermes is a particular case, and some of its products use significant trademarks like mass luxury goods.

In this way, HERMES has successfully become a semi-luxury and semi-top product. To maintain the status of the first brother in the industry, Hermes uses the best raw materials for manufacturing (purchasing personnel look for rare materials all year round and sign exclusive supply agreements with raw material suppliers with low output). And then, according to customer needs, customize it (note, customization is the leading service). It is almost to make the best product at any cost because only it is priced as high as hundreds of thousands or even millions without lack of customers. Because it is so well-known that the middle class and the new rich are eyeing it reduced to a semi-mass luxury, it may be the most successful top product. Other tops, such as John Lobb, have a side business that provides leather shoes for Hermès. Because Hermès did not overestimate itself, thinking that it would be able to produce the best shoes if it could make leather goods.

Simply put, Hermès products are probably the best. In front of it, other mass luxury brands are only mid-range

Let’s talk about Hermès first. For the best leather, Hermès picks it first and pays the highest price.

The industry knows that, for example, a batch of 1,000 pieces of calfskin does divide into five grades. The highest first-class has ten pieces. Hermes wants all of them. Other brands can offer up to 500 dollars, and Hermes 1,000 dollars. OK, no one is fighting it. The same goes for crocodile skin.

The best craftsman it is not easy to become a Hermès craftsman. Skilled craftsmanship can not go wrong. It is hand-made and takes a long time, so the price is high.

Most importantly, excellent designers.

Hermès has more than 70,000 colors, so the scarves are stunning. A scarf is a complete work of art.

Well, since the best leather is from Hermès, the materials of other brands are far behind. . . .

How many other brands are hand-made? LV Gucci and the like, not sure if there is, what is certain is that if there is, the proportion is not much. . . .

Here is an information source from others.

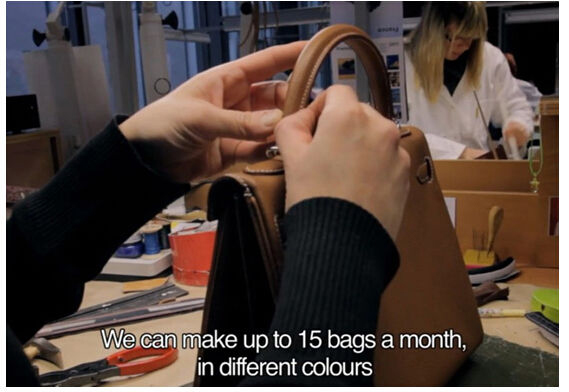

However, do you know how to make Hermès bags? If you are interested, you can look at the records here to learn about the production process of Hermes. Let's walk into the hand-made workshop of Hermès bags and decipher how to make this $10,000 Hermès wallet.

Welcome to the Hermès workshop

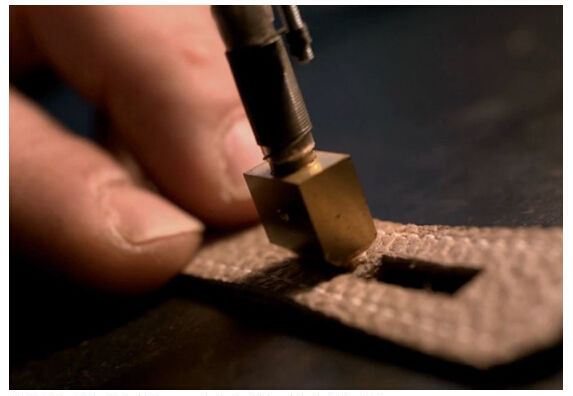

The first step in the entire production process of the Hermès bag is leather cutting. Here, the staff in charge of tailoring will carefully check the leather to confirm which piece of leather is suitable for processing into a Hermès bag.

The workers carefully check even the most minor details.

Employees receive at least one week of training before they are responsible for finishing and making leather.

Every employee in the factory is proud of their handmade.

The lady said she spend 1500 to 2000 hours on a drawing.

I think the above is the Hermès spirit that we should learn to focus on and conscientiously make our products. It is also the spirit of our lerings.

Contact: Lee

Phone: 008615812571762

E-mail: le@lerings.com

Whatsapp:008615812571762

Add: 3F,#4 ShangXing Road, XingAn ChangAn Town, DongGuan,China

We chat